On this page you can find examples of many of the different types of projects we have worked on.

To find out how we can help with your problem, please call us today on 07885 832023 or visit our contacts page .

This roof had been under pressure from the start. The stains on the roof were caused by the presence of permanent standing water, mainly caused by the roof not having falls. Owing to budget restrictions, a full tapered fall system was unaffordable, so with Proseal Smith Roofing Ltd's experience, we worked with the client to create channels by using lower insulation boards. As the roof was having a 120mm insulation top up, putting these channels in place helped the roof to have no standing water. Proseal Smith Roofing Ltd then applied a full bur two-coat fibre glass system.

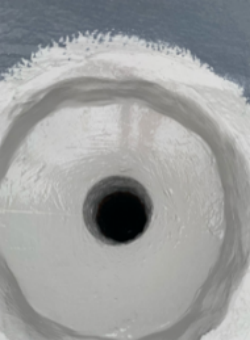

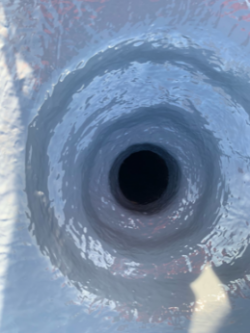

These pictures demonstrate how a felt outlet is converted into a liquids outlet. Proseal Smith Roofing Ltd ensured the outlet was blocked off to prevent debris from falling down.

We then started cutting out metal flanges.

All metal flanges were removed.

The old felt and bitumen were cut back to the original.

The area was cleaned down and metal primer applied.

Two coats of fibre glass system was applied.

The new outlet covers were put back in place.

People choose Proseal Smith Roofing Ltd because they know we take pride in what we do.

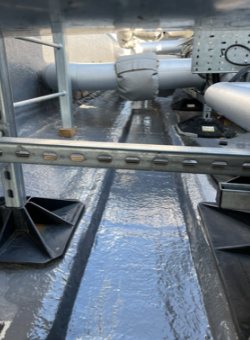

Full clean down on top and around.

After shot

This leg was dismantled to ensure a full clean.

Two coats of our fibre glass system was applied once the cured leg was refitted.

All the roof was now fully coated.

All works complete.

The job included some tricky areas to tackle.

The images below both show the completed job.

This old, lead roof had many weak areas because of the age of the lead. It required a full clean down, a jet wash and the application of two coats of our fibreglass system.

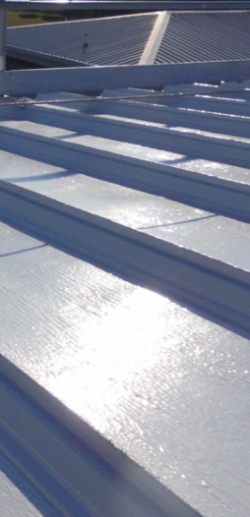

This metal roof was suffering with corrosion. A full jet wash was required, together with the cleaning of all corrosion back to clean metal. Our employees taped all the seam joints with bandage tape and applied fibreglass to all bolt heads. They also applied two coats of polyurethane liquids.

Sometimes we are asked to work on slightly different projects and this was no exception. A lady in her 90s who was still caring for her son who is in his 60s. The son had a fall in the garden with it being uneven. As he is not steady on his feet, he wasn’t allowed back outside until the problem was rectified. We put some ideas together, including the fact that the garden needed to be low maintenance and that the clients did not want to lose their planters as they grew all their own vegetables. The before and after shots here show how we widened the path to make access easier and installed a new lawn.

The bay window of this property had suffered after thieves had stolen its old lead, leaving it open to the elements. Firstly, a full clean down was required.

Vapour control layer, felt sticky back with new GRP trims.

Two coat fibre glass system.

All weather tight.

This system had failed because it had been wrongly laid. This needed all gutter lining to be stripped back to its original base, a clean down and the application of two coats of our fibreglass system.

Stripping back to original base.

Two coats of fibreglass system.

Back to working order.

This project shows how we create the perfect seal. Full plyboard out. VCL felt. Two coat fibre glass system.

Framing out.

Plyboard finish.

Two coat fibre glass system.

Poor detailing caused water ingress. It was stripped back enough to allow water to pass through and sealed with two coat fibreglass system.

These images show our cold-applied, thermal upgrade two coat fibreglass system.

With this problem, a split in the mortar had caused damage. The chimney was stripped back and the mortar replaced.

The problems with this chimney had been causing damp patches internally because of old, broken down mortar. The work needed to correct this problem was a full grind chase to all stone joints, full repoint, chimney pots stripped back, cleaned up and refitted.